When smoke clears and the sirens fade, the real work begins—safely. This guide walks property owners and facility managers through fire cleanup safety protocols, with a practical focus on containment, PPE, and negative air. If you’re facing fire damage in the Carolinas, TSIAC International can help you execute these steps correctly and efficiently.

Why safety-first matters after a fire

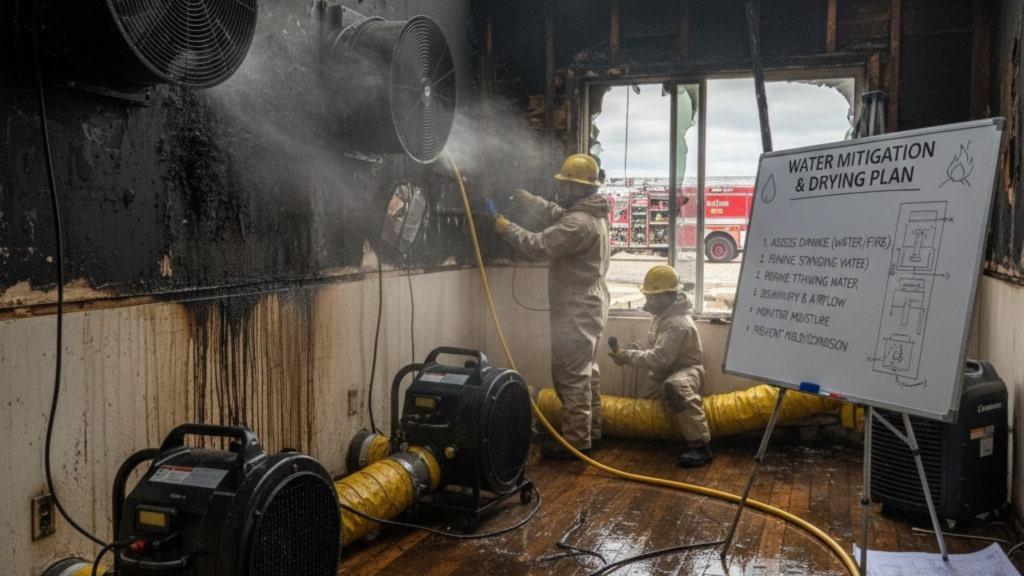

Fire scenes are complex. Soot particulates are acidic and ultra-fine; water used to extinguish flames can drive contaminants into hidden cavities; and burned building materials may release toxic compounds. Disturb them without a plan and you spread contamination, create inhalation hazards, and risk secondary damage to the rest of the building. Three pillars keep your team and occupants safe while preventing cross-contamination:

- Containment (isolate and seal the work area)

- PPE (protect workers from inhalation, contact, and penetration hazards)

- Negative air (pull contaminated air out through HEPA filtration and maintain pressure control)

Below is a field-tested, step-by-step approach.

1) Containment: keep contaminants where they are

Goal: prevent smoke residue, soot, and debris from migrating into clean areas.

A. Define the work zone

- Walk the site and mark the primary fire-impacted spaces and any adjacent rooms with visible soot or odor.

- Identify routes for material removal and a separate path for clean entries/exits where possible.

B. Seal the envelope

- Install 6-mil poly sheeting from floor to ceiling to enclose the work zone.

- Tape and seal penetrations (HVAC registers, light fixtures, chases, cracks around doors).

- Add zipper doors or framed doorways with overlapping flaps for controlled access.

- Protect floors with ram board or poly + slip-resistant mats.

C. Protect building systems

- HVAC off in the work area. Seal supply and return vents to prevent system contamination.

- If the rest of the building requires climate control, isolate that air handler from the work zone.

D. Establish clean/dirty transitions

- Create a decon vestibule (often a two- or three-chamber setup) immediately outside the contained space:

- Chamber 1: dirty side (bag-out area for debris and disposable PPE)

- Chamber 2: intermediate (hand/face cleaning station, tool wipe-down)

- Chamber 3: clean side (PPE donning)

Pro tip: Label everything—“HOT ZONE,” “DECON,” “CLEAN”—so subs and vendors don’t inadvertently breach the barrier.

2) PPE: protect the people doing the work

Goal: prevent inhalation of fine particulates and contact with irritants/carcinogens found in post-fire residues.

A. Respiratory protection

- Minimum: NIOSH-approved half-face respirator with P100 filters for soot particulates.

- When to upgrade: If strong odors/volatile compounds are present, use combination P100/OV cartridges (particulate + organic vapor).

- Fit testing: Ensure each worker is fit-tested and medically cleared. Facial hair compromises the seal.

- Change-out schedule: Replace filters based on load, odor breakthrough, or manufacturer guidance.

B. Body, hand, eye, and foot protection

- Coveralls: Disposable, hooded coveralls (e.g., Type 5/6) to prevent tracking soot to clean areas.

- Gloves: Nitrile (chemical splash) or cut-resistant gloves depending on task and debris. Double-glove when bagging waste.

- Eye/face: Safety glasses with side shields for general work; face shields for scraping/wiping overhead.

- Footwear: Safety-toe boots with slip-resistant soles; use disposable boot covers inside contained zones to reduce cross-tracking.

C. Donning and doffing (the right way)

- Donning (clean side): sanitize hands → base layer → coveralls → respirator → eye protection → gloves → boot covers.

- Doffing (dirty side): remove gross debris first → wipe down gloves → peel off coveralls inside-out → bag immediately → remove boot covers → clean gloves → remove eye protection → remove respirator last → sanitize hands and face.

Pro tip: Train your crew to treat PPE like a system. Most exposures happen during doffing and breaks.

3) Negative air: control the direction air (and contaminants) move

Goal: keep the work area under negative pressure so air flows into the containment and out through a HEPA-filtered exhaust—never the other way around.

A. Equipment and setup

- Negative Air Machine (NAM): Portable unit with a HEPA H13 or better filter.

- Ducting: Run layflat duct from the NAM to an exterior discharge point (window/door panel). Seal all joints with tape/clamps.

- Make-up air: Ensure enough make-up air pathways into containment (through controlled zipper doors or make-up vents) so the NAM doesn’t collapse your sheeting.

B. Pressure targets and verification

- Aim for a consistent, measurable negative pressure relative to adjacent spaces (commonly verified with a differential manometer).

- Use a smoke pencil at door seams to confirm air is moving into the work zone.

- Log readings at the start, mid-shift, and end of day—or set up a continuous monitor if available.

C. Air changes and filtration

- Size your NAM to provide adequate air changes per hour (ACH) for the volume of the containment. Higher ACH improves capture of fine particulates and odors.

- Maintain and inspect pre-filters daily; replace clogged pre-filters to protect the HEPA and maintain airflow.

Pro tip: Position the NAM intake opposite your decon/entry to create a sweeping airflow path across the workspace.

4) Cleaning sequence: from dry removal to fine particulates

Goal: remove residues efficiently while minimizing re-aerosolization.

- Dry removal first: HEPA vacuum ceilings, walls, and surfaces before wet cleaning. This reduces smear and prevents grinding soot into pores.

- Wet wipe/wash: Use fire-specific detergents/degreasers following label directions. Rinse with clean water.

- Porous vs. non-porous: Non-porous surfaces clean more completely; evaluate porous items (acoustic tiles, insulation, charred drywall) for disposal.

- Odor mitigation: After source removal and cleaning, deploy odor control (hydroxyl or ozone—ozone only in unoccupied spaces with strict safety controls).

- Final HEPA pass: Repeat HEPA vacuuming after surfaces are fully dry to capture fine particulates that settled during cleaning.

5) Waste handling and bag-out

Goal: move debris out without contaminating clean areas.

- Double-bag debris in 6-mil poly; goose-neck and tape.

- Use the dirty side of the decon to stage and seal bags.

- Transport along the pre-planned route; never through public or finished areas if you can avoid it.

- Document disposal according to local requirements—especially for appliances, paints, or chemicals affected by heat.

6) Special hazards: when to stop and escalate

Some materials demand specialized handling. Pause and consult professionals if you encounter:

- Compromised structures (unsafe framing, falling hazards)

- Suspected asbestos (textured ceilings, floor tiles/mastic, pipe insulation in older buildings)

- Lead-based paint (pre-1978 homes)

- Heavy chemical/solvent odors or unknown containers that heated in the fire

TSIAC International’s teams are experienced in demolition, abatement, and fire cleanups—so if your project crosses into these categories, bring in a licensed crew to stay compliant and safe.

7) Post-clean verification: don’t skip the proof

Goal: confirm that contamination is contained, air is safe to breathe, and surfaces are clean.

- Visual inspection: no visible soot, streaking, or residue—especially at edges and high points.

- Olfactory check: lingering smoke odor often means remaining source material—re-inspect cavities, carpet pads, and insulation.

- Air and surface sampling (as needed): particulate or odor markers can validate remediation in sensitive settings (medical, childcare, food).

- Pressure off, barriers down (in order): after passing checks, shut down the NAM, remove barriers methodically, and clean the transition zones.

Quick checklist (pin this in your trailer)

- ☐ Build, seal, and label containment with clean/dirty/decon zones

- ☐ Shut down/seal HVAC in the work area

- ☐ Don appropriate PPE (fit-tested respirators, coveralls, gloves, eye/foot protection)

- ☐ Start negative air and verify pressure direction with a meter or smoke pencil

- ☐ HEPA vacuum → wet clean → rinse → HEPA vacuum again

- ☐ Double-bag and bag-out through decon; document disposal

- ☐ Verify results; demobilize barriers in sequence

Need help? Bring in a coordinated crew.

Fire cleanup is not a single trade—it’s coordination between safety, demolition, and restoration. TSIAC International brings those disciplines together so you get a contained jobsite, protected workers, and a clean, ready-to-rebuild space.

One helpful resource: To learn more about respirator selection and use, see OSHA – Respiratory Protection.

If you’d like us to build the containment, run negative air, and handle the cleanup end-to-end, reach out to TSIAC International for a site assessment and plan tailored to your building and timeline.