Property owners must never enter fire-damaged buildings without understanding life-threatening health risks. Fire damage creates invisible toxic hazards including carcinogenic particles, respiratory dangers, and structural threats that can cause immediate harm or devastating long-term health problems.

Understanding Fire Damage Health Risks in Local Properties

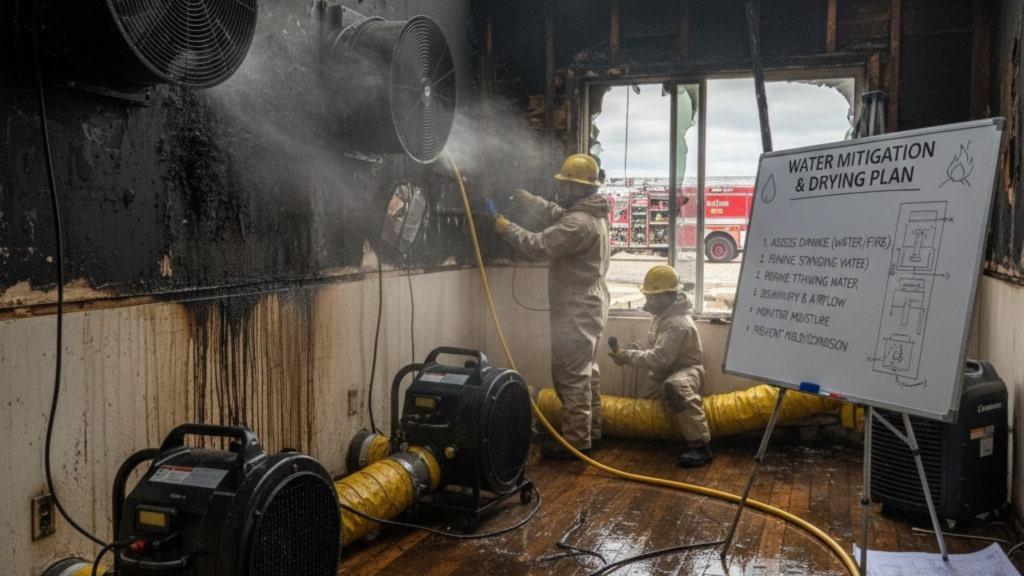

When fire strikes homes and businesses, property owners naturally want to assess damage and begin recovery immediately. However, fire-damaged properties present unique health hazards that extend far beyond visible damage. The combination of burned materials, firefighting water, and humid coastal climate creates a perfect storm of toxic exposure risks that can permanently impact your health and your family’s wellbeing.

Local architectural character, with many historic homes built before modern safety standards, compounds these risks significantly. Properties constructed before 1980 often contain asbestos in insulation, flooring, and roofing materials that become airborne when damaged by fire. Beautiful antique homes may also contain lead-based paints that release toxic heavy metals during fires, creating neurological and developmental health risks that are particularly dangerous for families with children.

The Invisible Dangers Lurking in Fire-Damaged Properties

Fire damage creates a toxic environment that looks deceptively manageable to untrained property owners. When materials burn, they release dangerous gases including carbon monoxide, hydrogen cyanide, and volatile organic compounds that can linger in humid air for weeks after a fire. These invisible contaminants pose immediate respiratory risks that can cause severe breathing difficulties, headaches, nausea, and even loss of consciousness in previously healthy individuals.

Coastal humidity exacerbates these dangers by trapping toxic particles and creating conditions where harmful substances remain concentrated longer than in drier climates. The moisture from both firefighting efforts and natural humidity accelerates the formation of dangerous mold growth, which combines with existing fire toxins to create compounded health threats. This unique environmental combination makes local fire damage particularly hazardous compared to similar incidents in other geographic regions.

Microscopic soot particles penetrate deep into lung tissue, causing inflammation and breathing difficulties that are especially dangerous for residents with pre-existing respiratory conditions common in humid coastal environments. These particles carry carcinogenic substances directly into your respiratory system, where they can cause both immediate distress and long-term health problems including chronic obstructive pulmonary disease and various cancers.

Carcinogenic Exposure Risks Specific to Historic Architecture

Historic charm comes with hidden health risks when fire damage occurs. Many beloved antique homes and commercial buildings contain materials that become extremely dangerous when burned. Asbestos fibers, commonly found in older buildings, become airborne during fires and cause mesothelioma and lung cancer with even minimal exposure. These fibers are particularly insidious because health effects may not manifest for decades after exposure, making immediate protection absolutely critical.

The beautiful lead-based paints that adorn many historic properties release toxic heavy metals when damaged by fire. Lead exposure causes neurological damage, developmental delays in children, and cognitive impairment that can be permanent. Given local family-oriented communities and tourist industries, protecting children and visitors from these invisible dangers becomes a serious public health and legal liability concern.

Polycyclic aromatic hydrocarbons, cancer-causing compounds produced when organic materials burn, are absorbed through both skin contact and inhalation. In humid environments, these compounds remain active longer and pose increased risks. The combination of historic building materials and coastal environmental conditions creates a uniquely dangerous situation for property owners dealing with fire damage.

Structural Hazards Compounded by Climate Conditions

Humid coastal environments affect building materials differently than dry climates, creating unique structural dangers after fire damage. Steel beams and supports lose strength when exposed to high temperatures, and moisture accelerates corrosion of these weakened structural elements. Wooden supports may appear intact but have lost critical structural integrity, particularly dangerous in older homes where original timber construction methods may not meet modern safety standards.

Electrical hazards become exponentially more dangerous in humid environments. Fire damage to electrical systems creates electrocution risks that are amplified by moisture from both firefighting efforts and natural humidity. Water and electricity create deadly combinations, and coastal climate means these dangerous conditions persist longer than in drier regions.

Floor and ceiling collapse risks are particularly acute in historic properties where original construction methods and materials may already be compromised by age. Fire weakens these structures in ways that aren’t visible, and humidity can accelerate deterioration of fire-damaged structural elements. Beautiful but aging architecture requires specialized assessment by professionals familiar with historic construction methods and materials.

Health Impacts Amplified by Environmental Conditions

Unique coastal environments create conditions where fire damage health risks are more severe and persistent than in other locations. Humidity traps toxic particles and gases, extending exposure periods and increasing concentration levels of dangerous substances. This means residents face prolonged exposure to carcinogenic materials and toxic fumes that would dissipate more quickly in drier climates.

Respiratory problems are particularly concerning for residents because coastal environments already challenge many people with allergies and breathing difficulties. Fire damage exposure can trigger severe respiratory distress in individuals who previously managed mild environmental sensitivities successfully. The combination of existing environmental factors and fire damage toxins can cause permanent respiratory damage that significantly impacts quality of life in active, outdoor-oriented communities.

Long-term health implications include chronic respiratory conditions, various cancers, and neurological effects that may not manifest for years or decades. Close-knit communities mean that fire damage health impacts affect not just individual families but entire neighborhoods and social networks. The emphasis on historic preservation and community character makes protecting residents from these health risks a critical public safety priority.

Essential Safety Protocols for Property Owners

Property owners must understand that fire damage creates immediate life-threatening conditions that require professional assessment before any entry attempts. Local fire officials must declare properties structurally safe, and professional air quality testing must confirm safe conditions before anyone should enter fire-damaged buildings. This professional assessment is particularly critical because unique environmental conditions and historic architecture create complex safety challenges that require specialized expertise.

Structural engineers familiar with historic construction methods must assess building integrity for any significant fire damage. Antique buildings often use construction techniques and materials that behave differently under fire stress than modern construction. Professional assessment protects both immediate safety and long-term structural integrity of irreplaceable historic properties.

Air quality testing must evaluate specific contaminants common in fire-damaged properties, including elevated levels of toxic gases that persist longer in humid conditions. Professional testing should assess carbon monoxide, volatile organic compounds, particulate matter concentrations, and asbestos fiber counts that are particularly relevant to older building stock. Surface contamination testing for heavy metals, carcinogenic residue, and mold growth is essential given environmental conditions.

Personal Protection and Safety Equipment Requirements

When professional assessment confirms limited entry is absolutely necessary, property owners must use appropriate personal protective equipment designed for toxic exposure conditions. Standard dust masks are completely inadequate for fire damage exposure and provide false security that can lead to dangerous health consequences. Professional-grade respirators with P100 filters or supplied-air systems are minimum requirements for any fire damage exposure in properties.

Complete skin protection including disposable coveralls, chemical-resistant gloves, sealed eye protection, and dedicated footwear prevents absorption of toxic substances through skin contact. Humid environments increase skin absorption rates, making complete coverage absolutely essential. Proper decontamination procedures must be followed immediately after any exposure, including removal of all protective equipment in designated areas, proper disposal of contaminated materials, immediate showering, and separate washing or disposal of all clothing.

Residents must understand that inadequate protection during fire damage exposure can cause immediate health emergencies and long-term health problems that may require ongoing medical treatment and monitoring. The initial investment in proper safety equipment and procedures is minimal compared to potential medical costs and health impacts of toxic exposure.

Medical Care and Health Monitoring

Residents exposed to fire damage should seek immediate medical evaluation from healthcare providers familiar with toxic exposure and environmental health risks. Local medical facilities have specialists experienced in treating fire damage exposure, but proper documentation and early intervention are critical for optimal outcomes. Emergency medical attention is required for any breathing difficulties, chest pain, severe headaches, nausea, or signs of toxic exposure.

Establishing ongoing health monitoring with local healthcare providers protects long-term health and provides documentation for insurance and legal purposes. Regular pulmonary function tests, cancer screening protocols, neurological assessments, and blood tests for heavy metal exposure should be part of ongoing health management for anyone exposed to fire damage. Medical communities understand the unique environmental health challenges facing coastal residents and can provide specialized care and monitoring.

Documentation of all medical evaluations, treatments, and ongoing monitoring related to fire exposure protects both health and financial interests. Residents should maintain detailed records of exposure circumstances, dates, duration, and all health assessments. This documentation is essential for insurance claims and potential legal protection if others are exposed to fire damage on your property.

Special Considerations for Families and Vulnerable Populations

Family-oriented communities must pay special attention to protecting children, elderly residents, and pregnant women from fire damage exposure. Children are more susceptible to toxic effects because of developing respiratory and nervous systems, and they should never be allowed near fire-damaged properties under any circumstances. The emphasis on multi-generational families living in historic homes makes this protection particularly important.

Pregnant women face serious risks from fire damage exposure that can affect fetal development, making complete avoidance of fire-damaged areas essential. Growing young professional populations include many women of childbearing age who must understand these risks. Elderly residents may have compromised immune systems and existing health conditions that increase vulnerability to fire damage toxins.

Pet safety is also a significant concern for animal lovers. Dogs, cats, and other pets are vulnerable to the same toxic exposures that threaten humans. Pet-friendly communities should keep animals away from fire-damaged areas, watch for respiratory distress in pets, consult veterinarians about potential exposure, and apply the same decontamination principles to pet areas and belongings.

Working with Local Professionals and Service Providers

Property owners must understand the different priorities and expertise of various professionals involved in fire damage response. Health professionals focus on immediate safety, medical evaluation, long-term health monitoring, and regulatory compliance, while restoration companies prioritize property restoration, timeline efficiency, cost management, and insurance claim processing. Coordinating these different priorities requires clear communication and proper sequencing of services.

Prioritizing health assessments before restoration work begins protects everyone involved in the recovery process. Restoration companies experienced in historic properties understand the importance of proper safety protocols, but property owners must ensure that health protection takes precedence over restoration speed or cost considerations. Professional air quality testing, hazardous material assessment, and medical clearance should be completed before any restoration work begins.

Networks of certified industrial hygienists, environmental testing companies, occupational health physicians, structural engineers, and certified asbestos and lead inspectors provide specialized expertise for fire damage health assessment. Building relationships with these professionals before emergencies occur ensures rapid response and proper protection when fire damage strikes properties.

Insurance, Legal, and Documentation Considerations

Property owners must understand that proper health documentation protects both immediate medical needs and long-term financial interests. Many insurance policies cover medical costs related to fire damage exposure, but proper documentation ensures coverage and prevents claim denials. Detailed records of exposure circumstances, professional assessments, and medical evaluations are essential for comprehensive insurance protection.

Legal liability protection is particularly important for property owners in areas with tourism industries and historic property tours. If visitors, tenants, or neighbors are exposed to fire damage hazards on your property, documented safety measures and professional assessments protect against liability claims. Legal communities understand the unique challenges facing historic property owners and can provide guidance on liability protection.

Environmental liability is an emerging concern for properties where fire damage creates contamination issues. Professional assessment and remediation documentation protects property owners from future environmental liability claims. The emphasis on environmental protection and historic preservation makes proper documentation and remediation essential for long-term property protection.

Long-Term Health Protection and Community Recovery

Strong community spirit includes supporting neighbors and families dealing with fire damage health impacts. Establishing ongoing health monitoring protocols protects individual families and contributes to community health and safety. Regular medical monitoring including pulmonary function tests, cancer screenings, neurological assessments, and blood work for heavy metal exposure should be part of long-term health management for anyone exposed to fire damage.

Community education about fire damage health risks helps protect residents and visitors from unnecessary exposure. Sharing accurate information about safety protocols, professional resources, and health protection measures strengthens the entire community’s resilience and preparedness. Historic preservation communities can play a vital role in promoting safety awareness and proper response procedures for fire damage incidents.

Mental health support is also an important component of recovery from fire damage exposure. Trauma-informed healthcare providers understand the psychological impacts of property loss, health concerns, and community disruption. Comprehensive recovery includes addressing both physical health impacts and emotional trauma associated with fire damage and toxic exposure.

Prevention and Preparedness for Local Properties

Property owners can reduce fire risks through comprehensive prevention strategies that account for unique climate and architectural characteristics. Installing appropriate smoke detection systems, maintaining electrical systems in historic properties, creating defensible space around buildings, and developing family evacuation plans protect both property and health. Fire prevention resources provide guidance specific to historic properties and coastal environmental conditions.

Emergency preparedness includes maintaining emergency medical supplies, knowing locations of emergency medical facilities, keeping important health documents accessible, and establishing relationships with qualified professionals before emergencies occur. Emergency management resources provide community-specific guidance for disaster preparedness and response.

Building relationships with qualified health and safety professionals before emergencies occur ensures rapid response and proper protection when fire damage strikes. Professional communities include specialists familiar with historic properties, coastal environmental conditions, and toxic exposure assessment who can provide expert guidance during emergency situations.

Your Health and Safety Come First in Fire Recovery

Fire damage restoration is important for maintaining historic character and community resilience, but your health and safety must always take precedence over property concerns. The hidden health risks in fire-damaged properties can cause serious immediate harm and long-term health problems that may not manifest for years or decades. Unique environmental conditions and historic architecture create complex health challenges that require specialized knowledge and professional expertise.

Property owners should never enter fire-damaged buildings without professional safety clearance, use proper protective equipment when any exposure is necessary, prioritize health assessment and monitoring over property restoration speed, document all exposure and health impacts for medical and legal protection, and work with qualified health professionals who understand fire damage risks specific to local environments.

Remember that irreplaceable historic properties can be restored or rebuilt with proper expertise, but your health and your family’s wellbeing cannot be replaced. When facing fire damage, the short-term inconvenience of proper safety protocols is insignificant compared to the potential long-term health consequences of exposure to fire damage hazards in unique coastal environments.

If you’ve been exposed to fire damage, don’t wait for symptoms to appear. Seek professional medical evaluation immediately from healthcare providers familiar with toxic exposure, and establish ongoing health monitoring to protect your long-term wellbeing. Medical communities have the expertise to provide proper care and monitoring for fire damage exposure, but early intervention and proper documentation are essential for optimal outcomes.

Need Expert Fire Damage Safety Assessment? TSIAC International provides comprehensive fire damage health risk evaluations and safety consulting for Charleston property owners. Our certified specialists understand the unique challenges of historic properties and coastal environments. Contact TSIAC International today for professional assessment and guidance to protect your health and ensure safe property recovery. Don’t risk your family’s wellbeing—get expert help from trusted fire damage safety professionals.